永续性 Sustainability

按照传统纺织品染色制程计算,平均每一码布料需耗费22公升的水资源。现有的合成纤维染色系统是基于过时的天然纤维染色流程所制定,就如同给电动车充入汽油一样, 听起来明显不合适。涤纶纺织品的技术已经日新月异,为何我们仍然在使用传统水染制程? With traditional methods of coloring fabric, most manufacturers waste 22 liters of water for every yard of fabric. The current system for dyeing synthetic textiles is based on outdated methods for natural fibers. It’s like putting diesel in an electric car; polyester textile technology has come leaps and bounds, and yet we still do piece dye? Why?

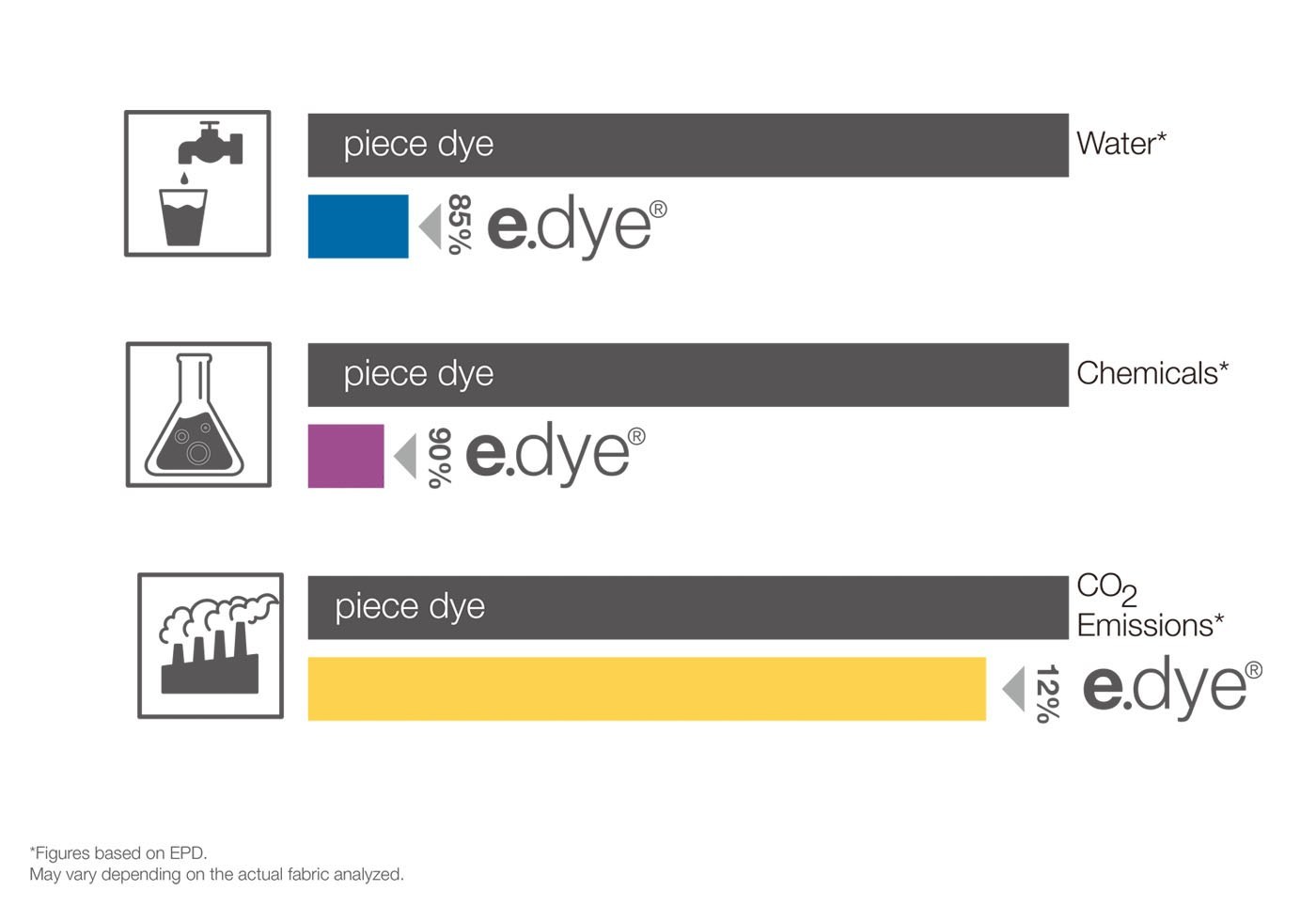

通过钻研原液着色流程,e.dye®呈现革命性的无水染色系统™,过程比传统制程减少消耗85%的水资源,布料具备卓越的色牢度,色彩系统提供高准度颜色匹配和再生产一致性。采用e.dye®无水染色系统™可以直接呈现水资源、化学品、能源的节省量。大幅度的降低传统生产流程所消耗的能源、碳排放,以及化学品。 By mastering the solution dyed polyester process, e.dye® Waterless Color System™ presents a paradigm shift in textile dyeing that results in a 85 percent water savings in comparison to traditional piece dyeing, superior colorfastness, and a precise color system for matching and consistency. The e.dye® Waterless Color System™ can demonstrate very clear water, energy and chemical savings. It requires less energy, reduces CO₂ emissions and limits the chemicals used in traditional production processes.

永续性商业模式是e.dye®的核心理念,更是我们的使命。不仅是维护地球环境,我们坚信珍惜工作伙伴,设备环境,和核心技术才能达到永续性的企业经营。 In addition, sustainable business practices are part of our Core Values, and our mission statement. Beyond taking care of our earth, we believe that taking care of our employees, our facilities and our technologies will result in the most sustainable solution.

点击页面了解更多关于e.dye®的产品和原液着色制程。 Learn more about the products we help create, and the process of solution dyed polyester.