原液着色 Solution Dye

原液着色是e.dye®精通并引以为傲的无水染色制程,为涤纶纺织品带来栩栩如生的色彩,同时大幅度降低水资源消耗、污染物质、以及有害化学品的使用。 Solution dye is the process e.dye® has mastered to bring beautiful colors to polyester textiles while reducing water consumption, pollution, and harmful chemicals.

首先,根据计算比例混合色母粒和塑料切片(原生或再生),过程由创新中心的专家操作,专业设备连动监测和分析混合制程。 First, we mix the Masterbatch in specific amounts with virgin or recycled PET chips, this mixture is controlled by our Innovation Center staff. Several computer-controlled machines mix and melt the PET chips and Masterbatch together.

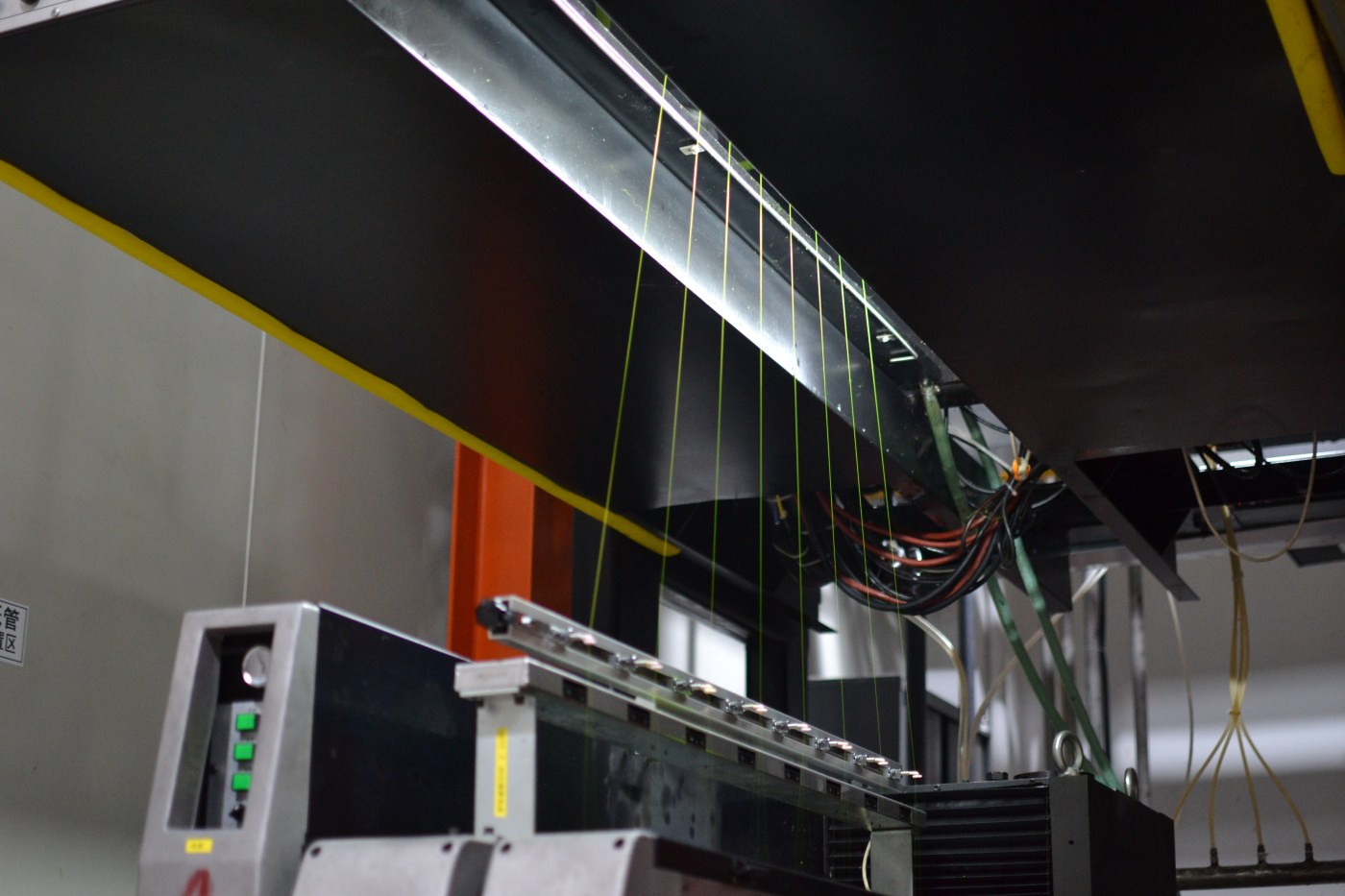

均匀混合的溶液在受热后,由设备挤压汇出成长丝纤维。 This ‘solution’ is melted in our extruder, after being mixed to a uniform dispersion. Once heated into a liquid state it is extruded into filament.

长丝纤维可根据不同纺嘴尺寸进行纺纱,汇出成纱线后,可进一步加捻纱线并根据需求织造成针织或平织布种。 These filaments can be various diameters, depending on the size of the spinneret, they get spun together into yarn. After that, texture can be added and the yarn can be woven or knit into textiles.

纱线卷取后需存放在厂区温控室,待确认后续布料和服饰生产排程才可取出。 Wound yarns are stored in a climate-controlled room at the Innovation Center, or sent out to make fabrics and garments!