技术 Technologies

色彩管理 Streamlined Color Management

e.dye®不只提供优异功能性的产品,我们的独家色彩管理平台颠覆产业的颜色管理制度。赋予纺织品颜色一致性,提升从样品到量产阶段的效率。受益于自主生产和控管色母粒,在 e.dye®上万个颜色中,每一个都有专属调色配方,这是原液着色产业中相当少见的。 In addition to all the performance benefits of e.dye®, another innovation is our Streamlined Color Management; a more effective system for textile color management. Because the e.dye® Waterless Color System™ delivers superior color consistency, we can more accurately predict color outcomes from samples to production. Each of e.dye® Waterless Color System™ 5,000 extruded yarn colors is bound to a specific color recipe in our Masterbatch – which we manufacture and control. This is unique in the world of solution dyed textiles.

专属调色配方是由颜料和染料以精密比例混合而成。在调色使用前,每个颜料和染料的采用都是经过高质量标准和内部测试。涤纶原料和颜料在精准的比例下混合而成,此配方是可以再复制的,确保我们提供的产品拥有业内最优异的颜色一致性。 Our color recipe’s are tightly controlled and tied to specific pigment and dyestuff formulas that we create. All of our pigment and dyestuff suppliers are selected according to high quality standards, and are tested internally before their selection and use. By using precise ratios of polyester and pigment, that are repeatable, we can guarantee the most precise color consistency available on the market.

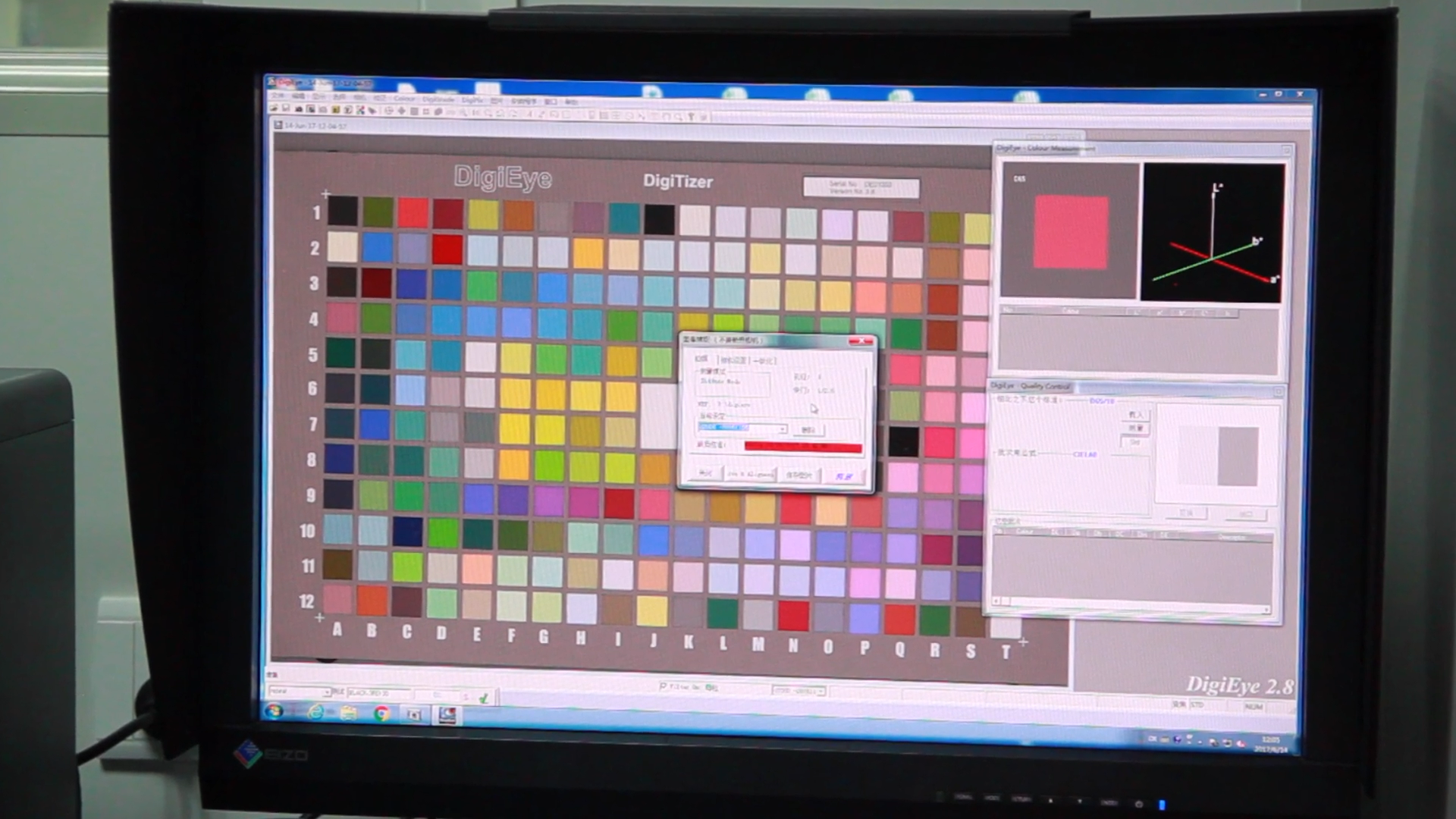

在e.dye®试点工厂,我们整合运用原液着色各项工段和精密制程设备,从抽纱、纺纱、到织造,产品的颜色一致性在产业内无可比拟,这些实物样品在产品初期开发中起到视觉参考的辅助效用,同时也提供开发后期的功能性标准参考。试点工厂将产品的各项工段参数建立后,就可以复制到我们的每个合作伙伴同步进行。 Since e.dye® has mastered the solution dyed polyester process, and utilizes computer-controlled dosing machines in our pilot factory, we have demonstrated an unrivaled color consistency in yarn extrusion, spinning and weaving. These samples become visual guides to select colors and products, which leads to further development and testing. All done in-house, these manufacturing steps must be replicated perfectly in partner mills and solution dye factories.

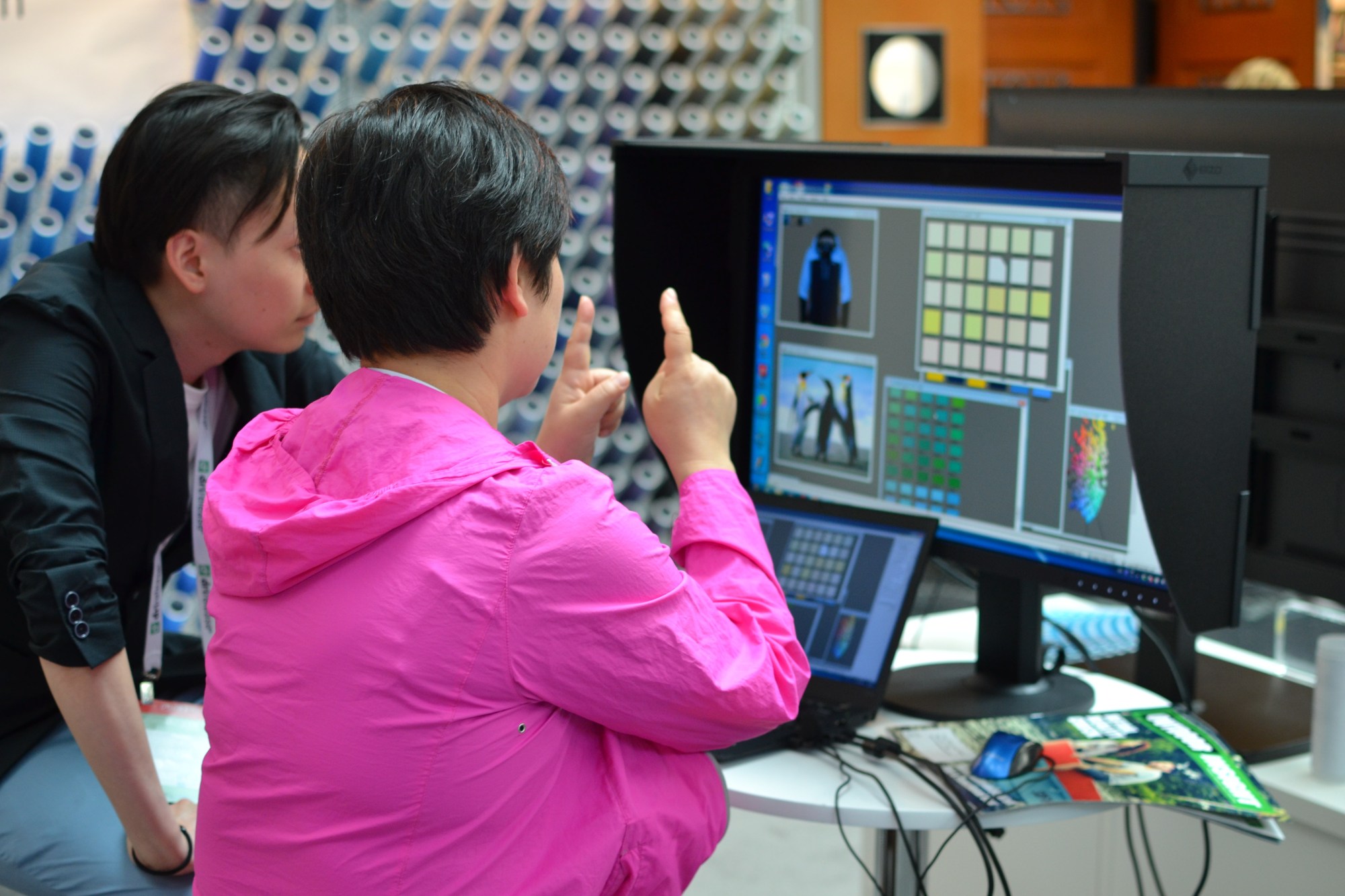

e.dye®完全了解产品开发过程中所面临的颜色不一致所造成的难处,我们的色彩团队致力于整合颜色解决方案,借由软件搭配硬件来突破这些产业瓶颈。详细信息,请透过info@e-dye.com联系我们。 It can be frustrating when results of color development do not match expectations. With our team of color physicists, we’ve selected a suite of color tools to improve textile color management for our industry. To learn more about the software and hardware we use, and to learn more about the Streamlined Color Management process, please send us an email info@e-dye.com.